On August 31st, residents from Sidney-Pacific and Ashdown House visited the Casella recycling facility in Charlestown. The facility collects raw, unprocessed recyclable material from collectors, sorts the material by type, and then sends the sorted materials to plants, both domestic and abroad, for processing. We received a personal tour of the facility, an overview of the recycling industry, and an inside look at how the plant operates.

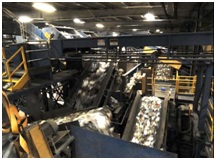

Thousands of tons of new recyclable material are brought into the facility every day. (Photo courtesy of Sunny)

Some interesting facts:

- Casella Recycling is a publicly traded company and receives no incentives from the government.

- The Charlestown plant, which is largest recycling plant east of the Mississippi River, sorts material from Vermont, New Hampshire, Maine, as well as the Boston metro area. The facility has over 140 conveyor belts and employs 150 people.

- The plant exports 50% of all sorted material to China, mostly comprised of paper and cardboard, as well as all Plastics 3-7.

- In 2010 alone, the facility sorted 1.5 million tons of recyclables.

- It costs $70 for one ton of trash to be disposed of at a landfill. Cities and municipalities receive $10 back for one ton of recyclable material sent to the facility.

- The facility uses “single stream” technology, which means that a mixture of all recyclable material is put on the same line. This also means that at home, we don’t have to pre-sort our recyclables.

- The facility uses the physical and optical properties of materials to physically separate them to a minimum purity of 95%, with tools like magnets, eddy current machines, and optical sorters.

Casella employees pre-sort out material that may damage equipment, like plastic bags and large metal objects. (Photo courtesy of Sunny)

The visit followed an environmental discussion dinner that took place earlier this August with participants from SP, Ashdown and Edgerton. The theme of the discussion was the export of plastics 3 through 7 to China, and it touched on related topics such as the health effects on Chinese workers. The discussion concluded with an open question on why these plastics are not processed here in America. On the trip to the Casella recycling facility, the head manager confirmed that Casella does export all plastics 3-7 unsorted together to China, where low-cost labor manually sorts through it. He noted the lack of demand for these plastics in America.

The visit confirmed that recycling is not just a theoretical sustainability goal, but a real and growing industry that supports local jobs and an international industry, saving millions of tons of waste in the process. The recycling center collects thousands of tons of material every day, material that would otherwise end up in a landfill. With Casella’s zero-sort policy, recycling is now easier than ever. Please do your part to recycle!

The visit confirmed that recycling is not just a theoretical sustainability goal, but a real and growing industry that supports local jobs and an international industry, saving millions of tons of waste in the process. The recycling center collects thousands of tons of material every day, material that would otherwise end up in a landfill. With Casella’s zero-sort policy, recycling is now easier than ever. Please do your part to recycle!

If you missed the visit, you can go on one of the following tours organized by the City of Cambridge (email recycle@cambridgema.gov for more info): September 21st 1:30pm, October 19th 1:30pm and November 15th 8:30am. You can also take the virtual tour here: http://zero-sort.com/

By Sunny Vanderboll and Jean-Philippe Coutu